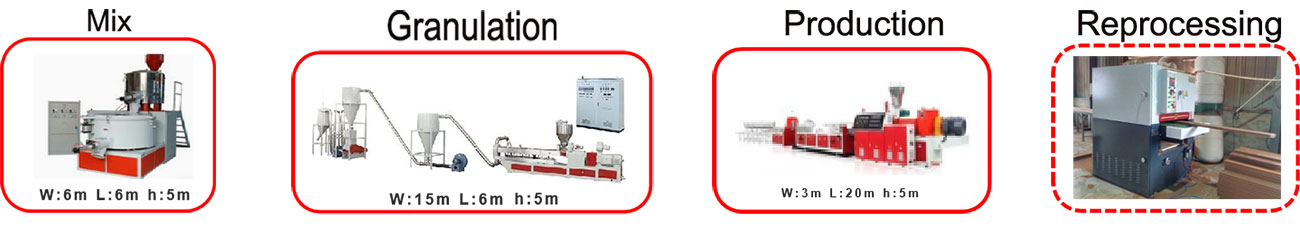

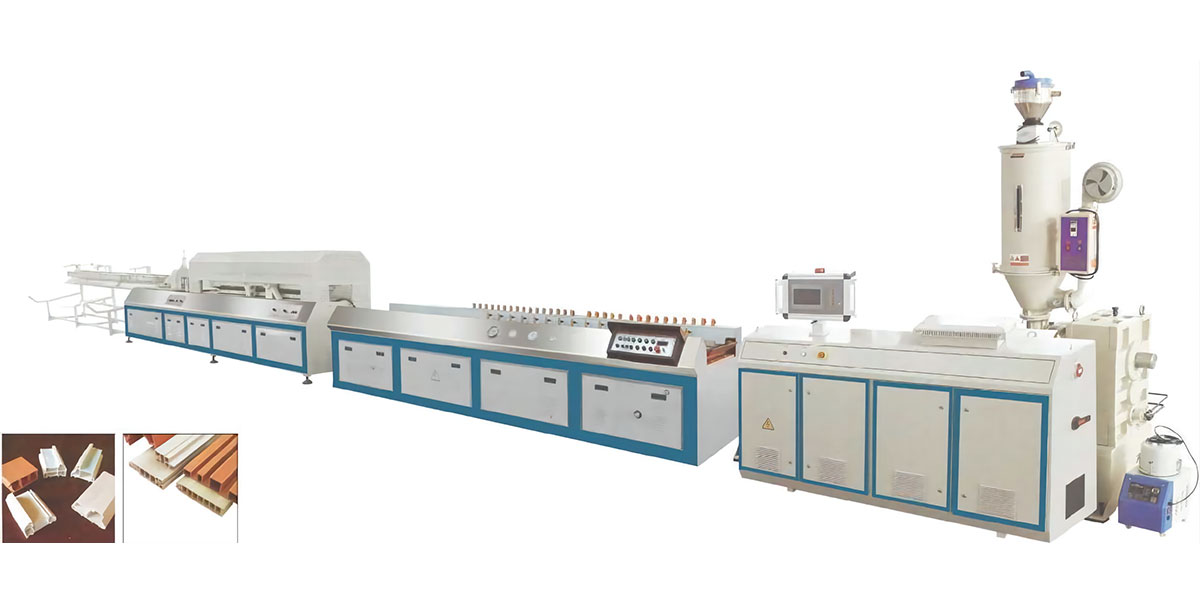

LSJ Single-Screw Extrusion Production Line Equipment

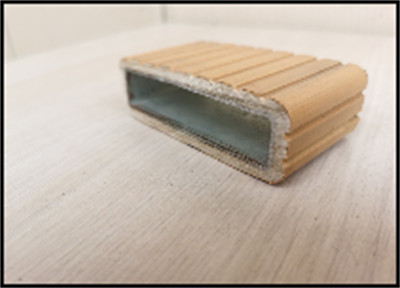

The screw design of LSJ series single screw extrusion production line equipment avoids high shearing and over-plasticization of raw materials. The raw materials are: PS, PP, PE, PC, PVC, which makes the surface wood grain of the extruded product unique and obvious, and the product is not Deformation, non-fading, fireproof, anti-corrosion, anti-moth, anti-aging and anti-ultraviolet. It is mainly used for the production of decorative ecological wood products such as Great Wall panels, partition panels, gussets, stair handrails, lampshades, photo frame lines, shutters, tile lines and so on.

| Main techinical parameter: | ||||

|

Model |

LSJ65 |

LSJ75 | LSJ90 | LSJ120 |

|

Screw diameter(mm ) |

65 |

75 |

90 |

120 |

|

Diameter ratio (L/D) |

20-40 |

|||

|

Main motor power (kw) |

18.5- 30kw | 22-37kw | 37-55kw | 55-75kw |

|

Barrel heating power(kw) |

12kw |

18kw |

30kw |

45kw |

|

Product maximum width (mm) |

110mm |

180mm |

240mm | 300mm |

|

Screw speed |

35-140rpm/min |

|||

| Note: The abowe paramelers are subject change without nolice | ||||

LSJ Series single-screw extruder

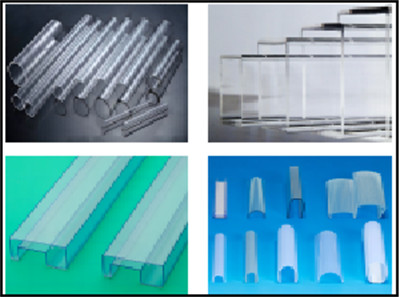

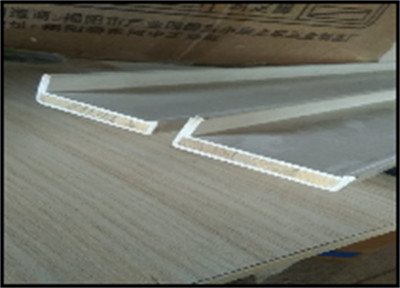

This series of equipment uses PVC, PE, PP, TPE, ABS, PS, PC, TPR, TPU, PU, PMMA and other raw materials, targeting: coil, fixed-length pipe, single-layer copper sheet, multi-layer copper sheet, wood board, profile and other coating products. According to different process requirements, the equipment is composed, such as: LSJ series single-screw main machine, LSJZ series conical twin-screw, preheating equipment, cooling and shaping equipment, cutting equipment, etc. The specific composition needs to be configured according to the specific requirements of the customer.

|

Specification |

LSJ single screw extruder |

LSJZ conical twin screw extruder |

||||

|

Model |

LSJ50 |

LSJ65 |

LSJ75 |

LSJ90 |

LSJZ51 |

LSJZ65 |

|

Screw diameter(mm ) |

30 |

65 |

75 |

90 |

51/105 |

65/132 |

|

Applicable raw materials |

PP, PE, PVC, TPE |

PP, PE, PVC |

||||

|

Diameter ratio (L/D) |

20-35 |

1 |

/ |

|||

|

Main motor power (kw) |

11-18.5kw |

15-30kw |

18.5-37kw |

22-55kw |

18.5kw | 37kw |

|

Barrel heating power(kw) |

8-2 |

8-12 |

8-15 |

8-15 |

7.9kw |

24kw |

|

Screw speed |

35-140rpm/min |

1-32 |

1-34.4 |

|||

|

Out put (kg/h) |

50 |

80 |

120 |

200 |

150 |

250 |

| Note: The abowe paramelers are subject change without nolice | ||||||

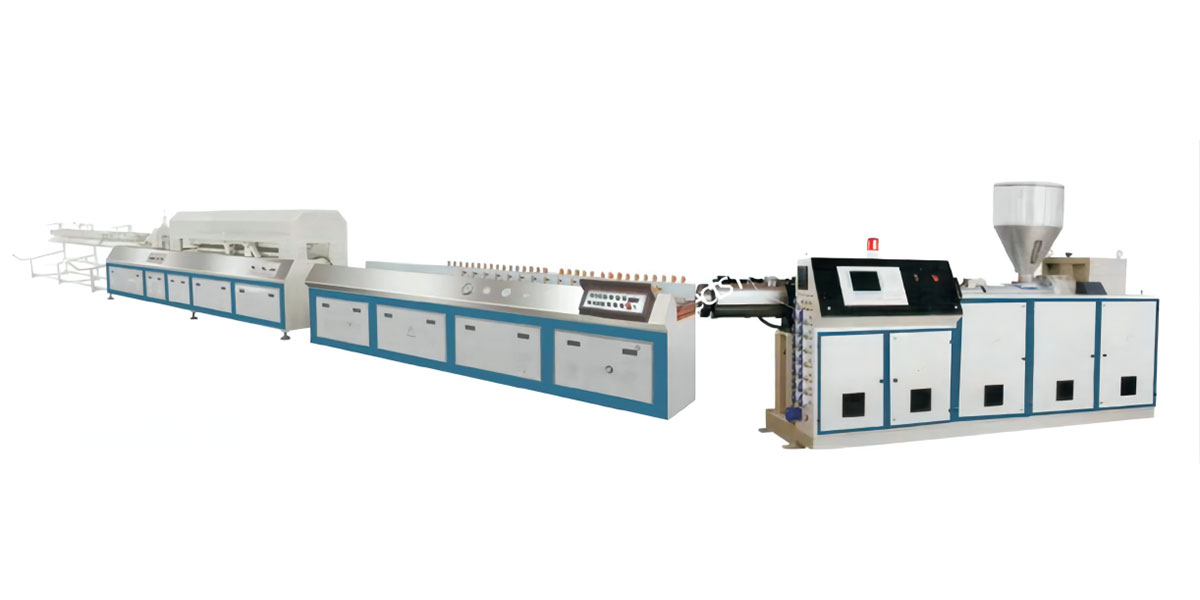

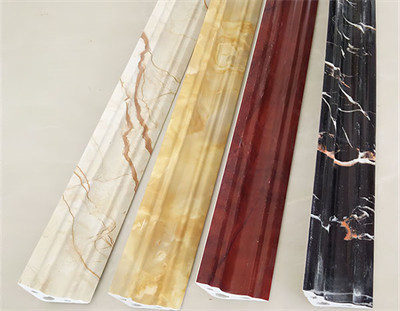

PVC,CPVC,UPVC WPC Profile Extrusion Production Line Equipmen

Mainly used for the production of electrical products such as PVC electrical cabinet line ducts, decoration threading pipes, open wire ducts and other electrical products; decoration materials such as top corner lines, waist lines, skirting lines, etc.; as well as window profiles, door casing lines and other products .

Different product requirements can be configured according to customer requirements to produce single-layer and multi-layer composite products; ASA and other materials can also be co-extruded on the surface to increase anti-aging, color difference years and other requirements.

| Main techinical parameter: | ||||

|

Model |

LJSZ-51 |

LJSZ-55 | LJSZ-65 | LJSZ-80 |

|

Screw diameter(mm ) |

51/105 |

55/110 |

65/132 |

80/156 |

|

Effective working length of screw(mm) |

1050 |

1150 |

1440 | 1800 |

|

Screw speed (r/min) |

1—32 |

1—32 |

1-34.4 | 1—38 |

|

Extruder motor |

18.5kw |

22kw | 37kw | 55kw/75kw |

|

Heating power (kw) |

7.9 |

18 |

24 | 34 |

|

Out put(kg/h) |

150kg/h |

180kg/h | 250kg/h | 480kg/h |

|

Center height (mm) |

1000 |

1000 |

1000 |

1100 |

| Note: The abowe paramelers are subject change without nolice | ||||

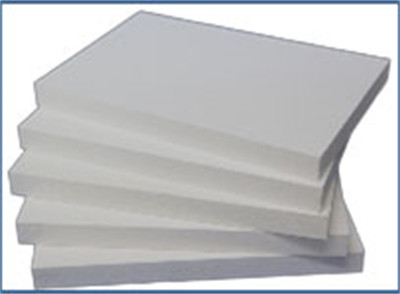

PVC crusting and foaming board, Single-sided/double-sided co-extrusion foaming board extrusion production line equipment

The extrusion equipment for PVC crusted foam board is composed of counter-parallel twin-screw extruder/ counter-conical twin-screw extruder, mold, vacuum cooling setting plate and eight-roller traction and other auxiliary parts. Wide range of application fields: high-grade cabinet furniture, advertising lettering materials, building decoration materials, interior decoration materials for automobiles, trains, ships, etc.

PVC single-sided/double-sided co-extrusion foam board extrusion production line equipment

Co-extrusion foaming board production line, through co-extrusion extruder, the surface layer does not foaming the rigid PVC surface layer, which improves the surface hardness of the foam board.

| Main techinical parameter: | ||

|

Specification |

Skinned foam board |

Single-sided/double-sided co-extruded foam board |

|

Products Width |

1220mm |

1 220mm |

| Products Thickness |

4-28mm |

4-28mm |

| Extruder Spedfication |

LSJZ80/156 |

LSJZ65/132&LSJZ80/156 |

|

Main Motor Power |

55/75KW |

37KW/55KW/75KW |

| Extrusion Output |

480KG/H |

650KG/H |

| Note: The abowe paramelers are subject change without nolice | ||